In today’s economy, maximizing the value of your data collection equipment is more important than ever. With technology moving at the speed of light, and flexibility and operating efficiencies of primary importance, making room for technology refresh is not only important, but essential to succeeding in today’s competitive marketplace.

With IT budgets getting smaller, legacy equipment is remaining out in the field longer. Although refreshing your technology may seem like a daunting task, consider the negative impact of keeping this equipment in the field and you’ll realize you can’t afford NOT to refresh.

Although refreshing your technology may seem like a daunting task, consider the negative impact of keeping this equipment in the field:

- Integration – with operating systems changing and communication speed increasing, legacy hardware will become more and more difficult to integrate with your software and communication network.

- Speed – communication speed is vital for field performance; if your mobile worker can’t communicate with your warehouse or headquarters, manual processes will add cost to your operations.

- Natural Elements – dirt, dust and debris are impossible to avoid. Over time, the buildup of contaminants will impact device performance and could result in costly repairs and maintenance.

- Repair Costs – With most device warranties and maintenance packages running from 1-3 years, the cost to repair and maintain older devices could easily equal the cost of a new device within 12 months of out-of-warranty service. And along with the costs of repairs on legacy equipment, the availability of parts and compatible software begin to narrow as devices age.

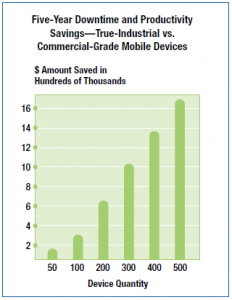

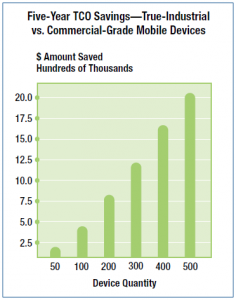

According to Honeywell’s The Importance of Mobile Computer Dirability and Ergonomics, using the wrong device grades can also be very costly:

The good news is you don’t have to dump 100% of your existing hardware and spend inordinate amounts of money on new technology in order to make your operations more efficient. With a smart IT strategy in place, and a progressive 3-5 year plan to implement new equipment, you’ll get more life out of better performing existing equipment and still be able to integrate new technology without slowing down performance.

Worker productivity decreases as technology ages. With productivity being a driving force in reducing costs and increasing profits, more time should be spend on the task itself vs. managing task challenges due to inadequate functionality or malfunctioning equipment. With data automation and wireless capabilities being the most beneficial features of technology today, why lose money and time through poorly performing equipment? Control costs and increase productivity by increasing the speed at which your workforce can complete their tasks. From warehouse operations to field service, increasing transaction speed and reducing error rate is critical to your business.

Looking for expert advice for your mobile fleet? Contact L-Tron Corporation and we’ll provide a comprehensive, end-to-end plan to help you put together a technology refresh based on your current needs and budget requirements.